Setting New Standards in Audio Testing with AmpConnect 621 & SoundCheck 23

17-Feb-2025

Meret Audio Launches State-of-the-Art R&D Test Lab Featuring Listen, Inc. AmpConnect 621 and SoundCheck Suite

In a strong signal to the industry, Meret Audio today unveiled a cutting‑edge acoustic R&D facility built around Listen, Inc.’s flagship AmpConnect 621 multichannel test interface, seamlessly paired with the latest SoundCheck 23 test software. The investment underlines Meret’s commitment to rigorous performance assurance from prototype to production.

Precision Starts in the Lab

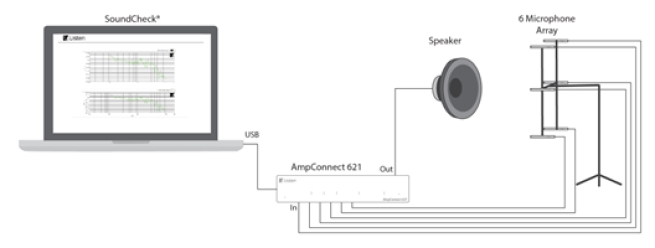

Meret Audio is established with bold ambitions and a strong engineering foundation. The recent installation of a dedicated test suite marks a meaningful escalation in technical capability. At the core: the AmpConnect 621, Listen, Inc. high‑resolution USB‑controlled interface. With support for up to six microphone inputs, dual line‑level outputs, and a built‑in mono power amplifier output, it offers comprehensive measurement flexibility for loudspeaker, headphone, and microphone testing.

Real‑Time Control, Maximum Accuracy - SoundCheck and AmpConnect

Meret’s setup runs the latest SoundCheck 23 suite, delivering a comprehensive audio testing environment covering frequency response, impedance, THD, Rub & Buzz, sound power, and more. The tight software–hardware integration lets users customize test sequences, adjust gain, stimulus level, and bias, or toggle amplifier outputs on the fly—ideal for operating in both bench‑top and automated production line contexts.

SoundCheck 23 builds upon decades of development to offer enhanced automation, tighter hardware integration, and broader scripting options. Meret leverages these features to capture extended performance datasets and tightly monitor manufacturing quality across their product lines.

Putting in the Work: Multi‑Channel Test Rigs

The lab features a state of the art set-up to capture acoustic data across multiple positions—ideal for applications like sound‑power measurements or evaluating multi‑driver systems. In streamlined production workflows, Meret uses sequences to automate frequent tests, with pass/fail criteria and digital I/O control integrated into test benches for full automation.

Every new device design goes through calibrated sequences: electroacoustic sweeps, impedance analysis, distortion and noise measurement, and Rub & Buzz evaluation. Calibration routines are managed through calibration editor, ensuring every sensor and amplifier meets traceable accuracy before data collection.

End‑to‑End Test Ecosystem: From R&D to Production

Meret Audio’s new facility serves dual roles. In the R&D lab, engineers fine‑tune new prototype hardware and firmware, validate electroacoustic performance, and iterate quickly using flexible sequence editor. Then, validated sequences are deployed to the production line, where automated rigs replay the same test protocols with the AmpConnect 621 controlling and monitoring measurement fixtures.

Production line control panels integrate with digital I/O features to start tests, capture results, and signal pass/fail outcomes—ensuring consistency from the first sample to final consumer models.

A Strategic Differentiator for Consumers

Meret’s approach emphasizes that their state‑of‑the‑art R&D system enables them to guarantee consistent SPL response, distortion control, and impedance stability, not just in the lab, but across every production unit. It positions them above competitors who may rely solely on specifications or third‑party testing.

With this new investment, Meret Audio is demonstrating a serious commitment to product performance excellence. This integrated test ecosystem ensures each device is benchmarked, calibrated, and production‑tested with full traceability and repeatability. It's a compelling message for both trade partners and end‑users: Meret builds not just innovative designs, but quality products built on measurement certainty.